Yintoni Ukubumba Isitofu?

I-injection molding yinkqubo yokubumba usebenzisa iimbumba.Izinto ezifana ne-synthetic resins (iplastiki) ziyafudunyezwa kwaye zinyibilike, kwaye emva koko zithunyelwe kwi-mold apho zipholile khona ukuze zenze imilo eyiliweyo.Ngenxa yokufana nenkqubo yokutofa ulwelo usebenzisa isirinji, le nkqubo ibizwa ngokuba yinaliti yokubumba.Ukuhamba kwenkqubo ngolu hlobo lulandelayo: Izinto eziphathekayo ziyancibilika kwaye zithululelwe kwi-mold, apho ziqina khona, kwaye ke iimveliso zikhutshwe kwaye zigqitywe.Ngokubunjwa kwenaliti, iindawo ezimilo ezahlukeneyo, kubandakanywa nezo zinemilo entsonkothileyo, zinokuqhubekeka kwaye zenziwe ngokukhawuleza kwimiqulu emikhulu.Ke ngoko, isitofu sokubumba sisetyenziselwa ukwenza iimpahla kunye neemveliso kuluhlu olubanzi lwamashishini.

Isitofu sokubumba sisetyenziselwa ukwenza izinto ezininzi ezinje ngee-spools zocingo, ukupakishwa, iminqwazi yeebhotile, iinxalenye zemoto kunye namalungu, iithoyi, iipokotho zepokotho, ezinye izixhobo zomculo, izitulo zesiqwenga esinye kunye neetafile ezincinci, izikhongozeli zokugcina, iindawo ezinomatshini, uninzi lwezinye iiplastiki. iimveliso ezikhoyo namhlanje.Isitofu sokubumba yeyona ndlela ixhaphakileyo yanamhlanje yokwenza iinxalenye zeplastiki;ilungele ukuvelisa umthamo ophezulu wento enye.

Isebenza Njani Ukubumba Isitofu?

I-Star Machining ibonelela ngesisombululo esipheleleyo sokuvelisa esigubungela yonke inkalo yoqinisekiso lwemathiriyeli ekrwada, ukwenziwa kwezixhobo, ukwenziwa kwenxalenye, ukugqiba, kunye nokuhlolwa kokugqibela.Iqela lethu leengcali zokuvelisa lizibophelele ekukuboneleleni ngelona nqanaba liphezulu lenkxaso yobuchwephesha kwiinkonzo zokubumba inaliti yeplastiki yazo naziphi na ubukhulu okanye ubunzima.

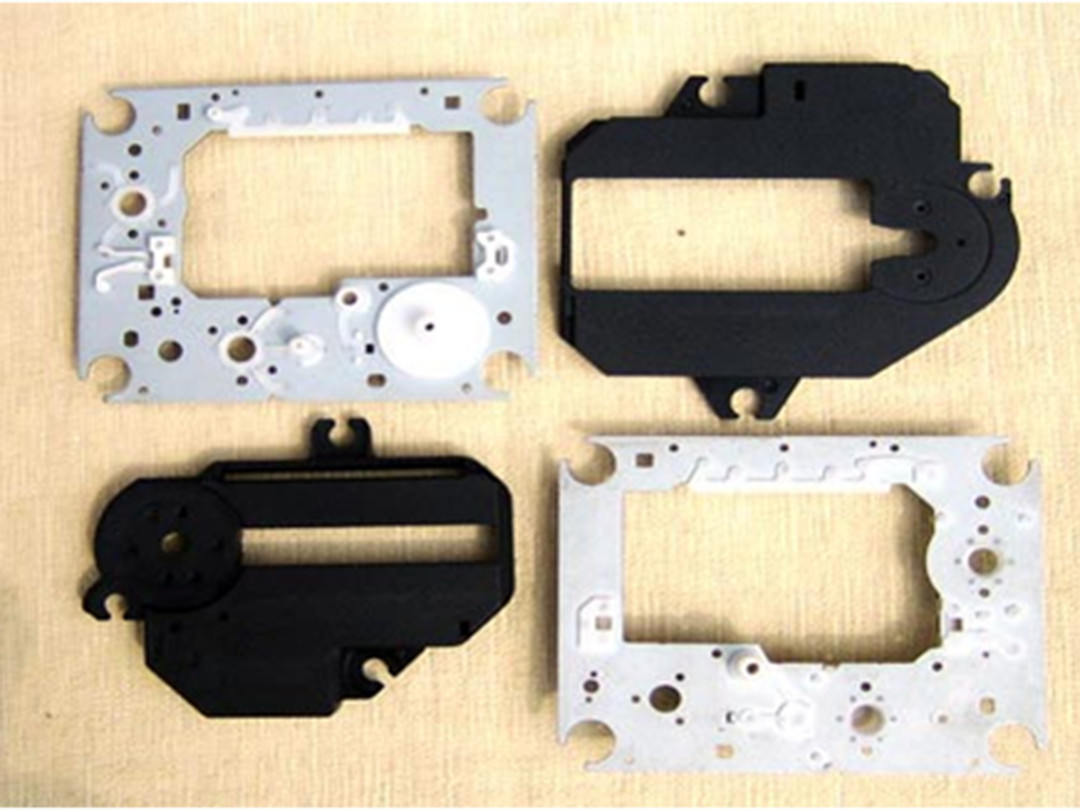

Ngokwesiqhelo ukwenziwa kwesitofu sokungunda kunokwahlulwa ngokwala manyathelo alandelayo:

1. Uhlalutyo lwenkqubo yeemveliso zeplastiki:

Phambi koyilo lokungunda, umyili kufuneka ahlalutye ngokupheleleyo kwaye afunde ukuba ingaba imveliso yeplastiki iyahambelana na nomgaqo wokwenziwa kwesitofu, kwaye kufuneka athethathethane nomyili wemveliso ngononophelo, kwaye imvumelwano ifikelelwe.Kubandakanya imilo yejometri, ukuchaneka komda kunye neemfuno zembonakalo yemveliso, iingxoxo eziyimfuneko, zama ukuphepha ubunzima obungeyomfuneko kwimveliso yokubumba.

2. Uyilo lwesakhiwo sokungunda.

3. Qinisekisa izinto zokubumba kwaye ukhethe iindawo eziqhelekileyo.

Ekukhethweni kwezixhobo zokubumba, ngaphezu kokuqwalasela ukuchaneka kunye nomgangatho wemveliso, ukhetho oluchanekileyo kufuneka lwenziwe ngokudibanisa nokusebenza kwangempela kunye nobuchule bokunyanga ukushisa kwefektri yokubumba.Ukongezelela, ukwenzela ukunciphisa umjikelezo wokuvelisa, sebenzisa iindawo eziqhelekileyo ezikhoyo ngokusemandleni.

4. Ukusetyenzwa kwamacandelo kunye nendibano yokubumba.

5. zama ukubumba.

Isethi yokubumba igqiba kuphela i-70% ukuya kwi-80% yenkqubo yonke yokuvelisa ukususela ekuqaleni koyilo ukuya ekugqityweni kwendibano.Impazamo ebangelwa kukungahambelani phakathi kwe-shrinkage eqingqwe kwangaphambili kunye neyona nto iyanciphayo, ukugudiswa kwe-demolding, kunye nefuthe lokupholisa, ngokukodwa impembelelo yobukhulu, indawo, kunye nokuma kwesango ngokuchaneka kunye nokubonakala kwemveliso, kufuneka kube. ivavanywa ngovavanyo lokungunda.Ke ngoko, uvavanyo lokungunda linyathelo eliyimfuneko ukujonga ukuba umngundo ufanelekile kwaye ukhethe eyona nkqubo yokubumba.

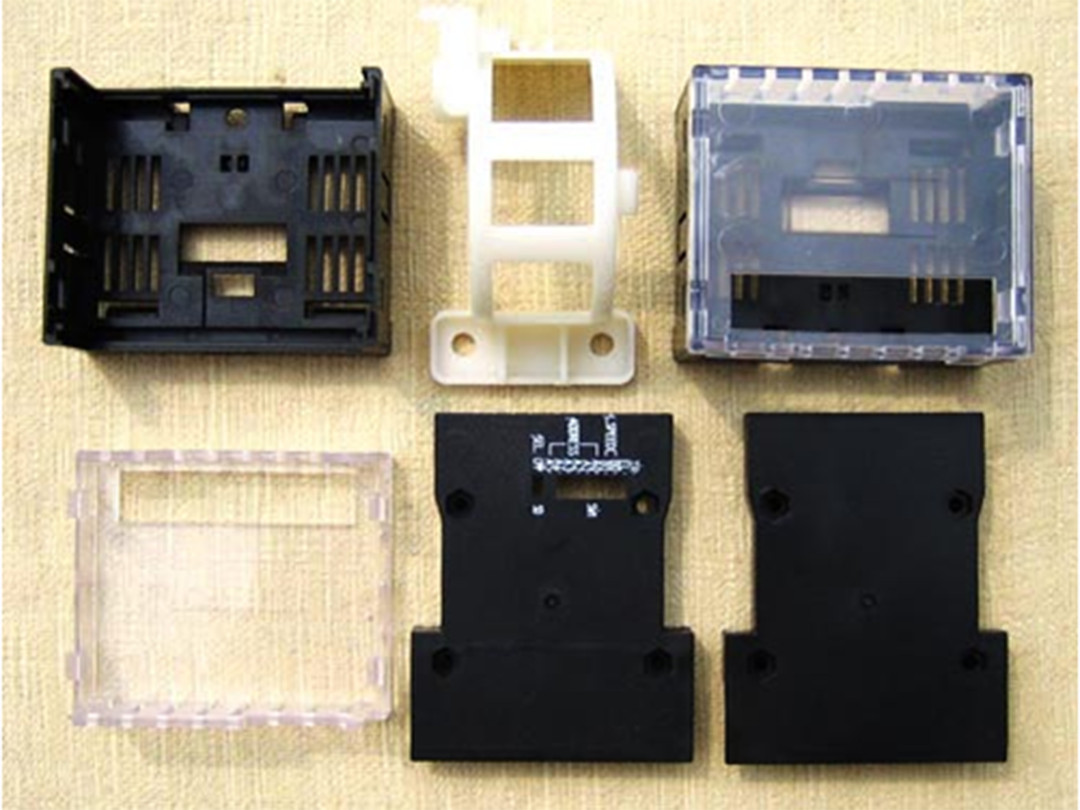

Isitofu sokubumba i-Applicitoni

Isitofu sokubumba sisetyenziselwa ukwenza iinxalenye zemilo entsonkothileyo yeesayizi ezahlukeneyo ezinobunzima obuncinci bodonga.Amalungu aqhelekileyo afana nekomityi, iikhonteyina, iithoyi, izifakelo zemibhobho yamanzi, izinto zombane, izamkeli zeefowuni, iikepusi zebhotile, iinxalenye zemoto kunye nezixhobo.

Ushishino lokutya kunye neziselo

Xa kuziwa ekubumbeni inaliti, ishishini lokutya kunye nesiselo lixhomekeke kakhulu kwizinto zeplastiki ukwenza ukupakishwa kwemveliso kunye nezikhongozeli.Ekubeni eli shishini kufuneka lihambelane nemigaqo engqongqo yococeko kunye nokhuseleko, ukubumba inaliti yeplastiki yinto ecacileyo yokuqinisekisa ukuba iinkcukacha ezahlukeneyo ziyafezekiswa, kubandakanywa ne-BPA-free, i-FDA-certified, non-toxic kunye nemigaqo ekhuselekileyo ye-GMA.Ukusuka kumacandelo amancinci njengeebhotile zebhotile ukuya kwiitreyi ezisetyenziswa kwizidlo zeTV, isitofu sokubumba sinika indawo yokumisa enye yazo zonke izinto ezipakishwayo kunye neemfuno zesikhongozeli seshishini lokutya nesiselo.

UkuVeliswa kweeMoto

Ishishini lale mihla lokwenziwa kweemoto liza kuthatha ukunciphisa ubunzima bomzimba njengowona mlinganiselo ungundoqo wokonga amandla.Kumazwe ngamazwe, isixa seeplastiki zobunjineli kwiimoto kuthathwa njengenye yezalathisi ezibalulekileyo zokulinganisa inqanaba leshishini leemoto lelizwe.Kulindeleke ukuba izinga lokukhula kweeplastiki zemoto liya kuba yi-10-20% kwixesha elizayo.Okwangoku, inani leplastiki elisetyenziswa kwiimoto zasekhaya libalelwa kuphela kwi-5-6% yobunzima besithuthi.Okwangoku, ishishini lokwenziwa kweemoto laseTshayina liya likhula unyaka nonyaka.Iya kuqhubeka inyuka unyaka nonyaka kwixesha elizayo.Uninzi lweemveliso zeplastiki ezisetyenziswa kwiimoto ziindawo ezibunjiweyo zenaliti, ezinje ngeebhampa zangaphambili nangasemva, iipaneli zangaphambili nangasemva, iipaneli zesixhobo kunye nezixhobo zazo, amavili okuqhuba kunye nezixhobo zazo, iigrili zeradiyetha, imiqolo emininzi, kunye nemibala yezibane ezidityanisiweyo.

Isitofu sokubumba yinkqubo yemveliso esekiweyo apho abenzi bokubumba iimoto bagalela imathiriyeli yeplastiki etyhidiweyo kwimingxuma yokungunda.Emva koko iplastiki etyhidiweyo iyaphola ize yomelele, aze umenzi akhuphe loo mveliso igqityiweyo.Nangona inkqubo yokubumba i-mold ibalulekile kwaye icela umngeni (i-mold eyilwe kakubi ingakhokelela kwiziphene), ukubunjwa kwenaliti ngokwayo yindlela ethembekileyo yokuvelisa iinxalenye zeplastiki eziqinileyo kunye nokugqitywa komgangatho ophezulu.

IsiXhobo saseKhaya/Ugcino lwaMandla

IiTV zemibala, iifriji, izifudumezi zamanzi, oomatshini bokuhlamba, iibhetri, iiseli zelanga, iigridi zelanga, iibhokisi zokuhlela inkunkuma, iitafile zangaphandle kunye nezitulo, ifenitshala, iitreyi ezinkulu zeplastiki kunye neebhokisi zenguqu, njl. Ezi mveliso ziza kuluntu, zijongene nokukhuselwa kokusingqongileyo. , ejongene nokonga amandla, kwaye kukho imfuno enkulu yeemveliso zokubumba inaliti.Kuyafuneka ukubonelela ngoomatshini bokubumba benaliti ngokubanzi ngokusebenza okugqwesileyo kunye nomlinganiselo wexabiso, oomatshini bokubumba inaliti yegwebu, oomatshini bokubumba inaliti ye-foam ye-microcellular, kunye noomatshini bokubumba inaliti ye-multi-layer composite.

Isixhobo, i-elektroniki, i-IT, amashishini ezonyango kunye namathoyizi ahlakaniphile

Le yimarike yemfuno enkulu elawulwa ngoomatshini bokubumba abancinci kunye nabancinci.Kule ntsimi, oomatshini abaninzi bokubumba bangenile kusapho, ikakhulu basebenza imisebenzi eyahlukeneyo yeenjini, izixhobo zombane, izixhobo ze-elektroniki, izihlanganisi, iiswitshi zokutshintsha, izinto ezininzi ezisebenzayo zombane kunye neemveliso ezidibeneyo zombane, iikhamera zendalo yonke, izixhobo zekhamera, izinto ezichanekileyo zonyango. kunye nezixhobo ze-ceramic ezintle.

Imarike yemfuno yolwakhiwo lweziseko zophuhliso

Uphuhliso loluntu alunakwahlulwa kulwakhiwo lweziseko ezingundoqo, kwaye eyona nxalenye ibalulekileyo kulwakhiwo lweziseko ezingundoqo kukwakhiwa kwemibhobho.Amandla orhwebo okufakelwa kwemibhobho edityanisiweyo eyahlukeneyo kunye nezixhobo ezinxulumene nokwakhiwa, ukunkcenkceshela, ukonga amanzi, unxibelelwano, iintambo kunye nemibhobho mikhulu.Umyinge wokukhula komyinge wonyaka wemibhobho kwilizwe lam ngama-20%.Ngo-2025, imibhobho yeplastiki iya kubalelwa kwi-50% yepayipi yonke, kwaye imibhobho yoxinzelelo oluphakathi kunye nephantsi kwizixeko iya kufikelela kwi-60%.Ukuba imfuno yonyaka yemibhobho yeplastiki yi-80,000 ukuya kwi-100,000 yeetoni ezisekwe kwi-50% yemibhobho yeplastiki, kunokucingelwa ukuba imfuno yentengiso enkulu yokufakelwa kwemibhobho yesitofu, kwaye uninzi koomatshini bokubumba isitofu banokuvelisa ukubumba inaliti ye-UPVC kunye ne-PE. ngaphantsi kwe-250-300mm.Ukufakwa kwemibhobho.

Kutheni ukhethe ukuSebenza ngeNkwenkwezi yokuBumba isitofu sePlastiki

Ezona zixhobo zokungunda ezigqwesileyo ziqala ngemathiriyeli ekrwada esemgangathweni, ulawulo olungqongqo lwenkqubo, kunye nabenzi bezixhobo abaziingcali.Ngumthengisi kuphela onamava eminyaka exhasa iinkampani ze-Fortune 500 ezinokuqinisekisa iziphumo eziphindaphindwayo kwiimfuno zakho zezixhobo zemveliso.Nazi ezinye iingenelo ukuba i-Star Machining ibonelela ngesixhobo sokuvelisa umthamo ophezulu kunye neenkonzo zokubumba iinaliti.

Uluhlu olupheleleyo lweeNkonzo

Sinikezela ngaphezu kokwenza izixhobo kunye neenkonzo zokubumba.Iphakheji yethu epheleleyo ibandakanya yonke inkqubo yokuvelisa oyifunayo kwisisombululo sophuhliso lwemveliso epheleleyo.

Impumelelo eqinisekisiweyo

Amawakawaka eenkampani zabo bonke ubungakanani obuvela kwihlabathi jikelele bakhethe ukusebenzisana neStar Rapid ukubanceda baphuhlise izixhobo zokubumba iinaliti ezintsha kunye neendawo ezigqityiweyo.Impumelelo yakho sisiseko sodumo lwethu.

Ukuchongwa kwezinto ezilungileyo

Uthotyelo lwakho lolawulo kunye noxolo lwakho lwengqondo ziqinisekiswa lisebe lethu elikhokelayo kwishishini lokuchongwa kwemathiriyeli.Abantu bayayithemba i-Star Rapid xa umsebenzi ngokuqinisekileyo kufuneka ulungile.

UPhuculo loYilo

Uyilo olubanzi lophononongo lwemveliso luza nesixhobo ngasinye kunye neprojekthi yoyilo lwemveliso.Uya kufumana iziphumo eziphezulu ngelixa ugcina ixesha kunye nemali.

Ukucaphula okuBukrelekrele kuyo yonke iProjekthi

Sixhasa iinjongo zakho zophuhliso ngokungabi namthamo omncinci womyalelo okanye ixabiso lemveliso yokubumba inaliti.Ukongeza, sinobunikazi be-AI yokucaphula i-algorithm ebonelela ngokukhawuleza, echanekileyo, kunye namaxabiso acacileyo kuyo yonke iprojekthi, ngalo lonke ixesha.

Jonga imizekelo yethu yokubumba inaliti